New Placement:

- Thermocoupler along axial probe

- Type K = Chromel-Alumel (+ leg and - leg respectively)

Temp. Range: –200°C to +1250°C

You can use the same sensor for warm-water tests now and hotter tests later without swapping technologies.Type K withstands mechanical shock and flow-induced vibration better better than T/D/E type thermocouples

- Type K with an Inconel or stainless sheath handles water, ethanol-water mixtures, and future propellant simulants well.

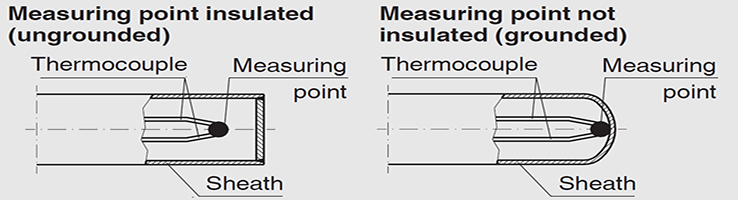

- Sheath:

- Source: https://www.wika.com/en-us/lp_sheathed_thermocouples.WIKA

- Type K = Chromel-Alumel (+ leg and - leg respectively)

Other Thermocouples for reference:

- Thermocouple Type K: NiCr-NiAl thermocouples are suitable for use in oxidising or inert gas atmospheres up to 1,200 °C / 2,192 °F (ASTM E230: 1,260 °C / 2,300 °F) with the largest wire size.

- Thermocouple Type J: Fe-CuNi thermocouples are suitable for use in vacuum, in oxidising and reducing atmospheres or inert gas atmospheres. They are used for temperature measurements up to 750 °C / 1,382 °F (ASTM E230: 760 °C / 1,400 °F) with the largest wire size.

- Thermocouple Type N: NiCrSi-NiSi thermocouples are suitable for use in oxidising atmospheres, in inert gas atmospheres or dry reduction atmospheres up to 1,200 °C / 2,192 °F (ASTM E230: 1,260 °C / 2,300 °F). They must be protected from sulphurous atmospheres. They are very accurate at high temperatures. The source voltage (EMF) and the temperature range are almost the same as with type K. They are used in applications where a longer service life and greater stability are required.

- Thermocouple Type E: NiCr-CuNi thermocouples are suitable for use in oxidising or inert gas atmospheres up to 900 °C / 1,652 °F (ASTM E230: 870 °C / 1,598 °F) with the largest wire size.

- Thermocouple Type T: Cu-CuNi thermocouples are suitable for temperatures below 0 °C with an upper temperature limit of 350 °C / 662 °F (ASTM E230: 370 °C / 698 °F) and can be used in oxidising, reducing or inert gas atmospheres. They do not corrode in moist atmospheres.

- Pressure sensor connected to tank through tube

- Might receive some varying pressure readings due to collisions from fluid, but will level out

- Useful for comparing pressure readings when collisions happen

- Pressure transducer + impulse line (stainless tube to prevent damage due to temp)

- Non-wetted setup that prevents the collision readings

- Strain gauge transducer, stainless-steel

- Might receive some varying pressure readings due to collisions from fluid, but will level out

- Thermal Cameras on bottom/top

- Constant processing may be excessive for OBC

- Better to have a pressure sensor on the lid of the tank to measure pressure drops.

- If used: Longwave IR camera

- Thermal Cameras placed axially to measure the surface temperature of tank (not verified)

- Since no MLI, can be used to give us a 2D temp field to complement axial thermocouple

- Longwave IR camera

Additional consideration:

- Omit MLI on outside because the top/bottom needs to be affected by the Sun

- We want to have a similar thermal load as the real tank, which has insulation that is not 100% effective.

OBC:

- For constant health checks we will need our own OBC. We need constant updates on the status of the tank for safety and it is unlikely that the satellite we are putting our payload in would want to share that much.

Total Sensors:

Mixing Subsystem Demo

...

- Thermocouples

- Pressure Sensor

- Liquid Level Sensor

- Flow Meter

- IMU/Accelerometer

- Voltage Sensor

- Heat-Flux Transducer/Platinum RTDs

- QCMs/RGAs

- Choose Pressure Sensor + liquid cooling method Angelina Costa

- Choose Thermocouples Emily Aleman Garcia

- Choose Thermal Camera Israel Garcia

- Contact Ansys for licenses or access Choose Pressure Sensors Israel Garcia21