Part | Component Status | Responsible Engineers |

|---|---|---|

| Booster Cup | Manufactured | Nicole C. 2024 |

Design

Requirements

...

- Shall contain soft goods prior to separation

- Shall withstand separation loads

- Shall separate from the nose cone/staging cone

Material: Fiberglass coupler tube

Risks: Holes shear during separation (insert link to past issues)

Features:

...

Details

The booster cup is made from a fiberglass coupler tube (4.6in long). It includes 12 radial holes of size 6-32

...

located 0.3 in. from

...

the edge of one side of the cylinder for interfacing with the diaphragm

...

.

Risks: Holes shear during separation (insert link to past issues)

Analysis

N/A

Manufacturing

Operations:

- Cut coupler tube to length on the horizontal bandsaw

- Sand faces to level

- Cut a piece of supporting material to go inside the cup while machining it

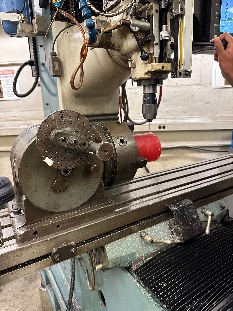

- Add holes with using the mill and radial indexer (*Note: add holes 0.3 inches from the side that has the better machine-finish)

- 12 holes equate to 3 1/3 turns for each hole on the 18-radius marker on the radial indexer in N-51

- Safety note: use air gun to blow away fiberglass dust as soon as each hole has been completed.

- Sand interior and exterior until slides smoothly into mission package tube