...

- unless you absolutely cannot create a profile without a 1/8" endmill (this is probably not true, this would require mean that you have a radius somewhere that is smaller than 1/8") do not use an 1/8" endmill

- in general, use the biggest endmill you can get away with (we used a 1/2" flat end for roughing and a 1/2" ball end for finishing) this reduces machining time and give you a better finish

- if you have a lot of CAM to run and it's going to take a long time, you should probably use a haas (area 51 has one, other places might as well) these are enclosed CNC mills that use flood coolant and can run much faster than the mills in Todd shop or the Deep

...

- waterjet the fins in Todd shop, including the holes for the screws

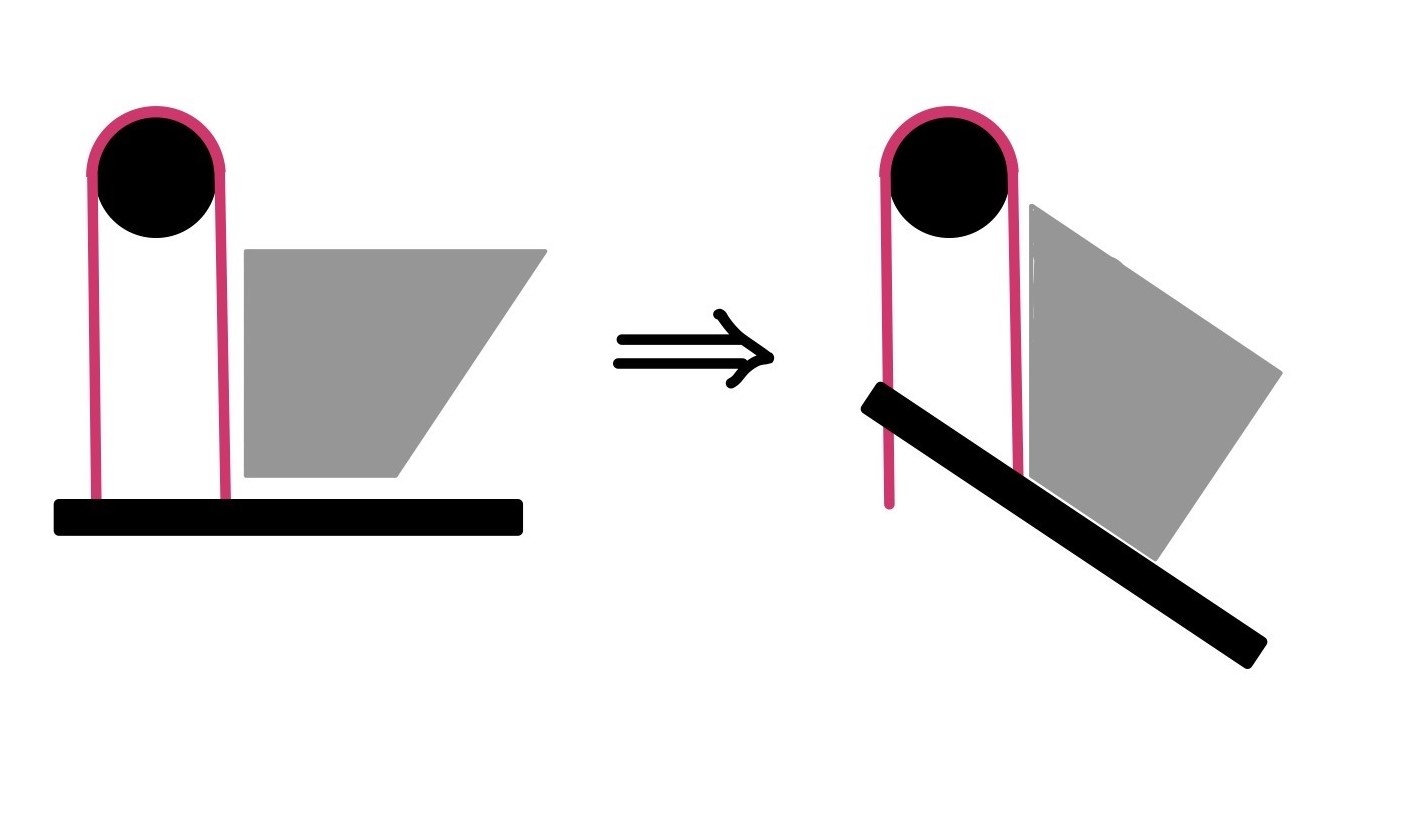

- round the leading and trailing edges of each of the fins

- we found the best way to do this was to use a file to get a rough profile and then using use a belt sander to finish the edges

- moving the bed of the belt sander to get the leading edge of the fin to be flush with the belt was very helpful

...