Ideas:

- Switch to a single pathway into one capsule instead of a branching fitting into two capsules

- Sandwich aluminum burst disk between two fittings and thread a modified firebolt (or two, for redundancy) into it

- What pressure are the gases from the black powder?

- TO-DO: Test sealing the e-matches in with hot glue instead of epoxy, would make integration less hazardous/quicker and re-use possible

- UNSUCCESSFUL, hydrostatic test resulted in leaking through the hot glue

- Could have been from a poor seal, but hot glue cools quite quickly and it doesn't flow to seal gaps as well as epoxy

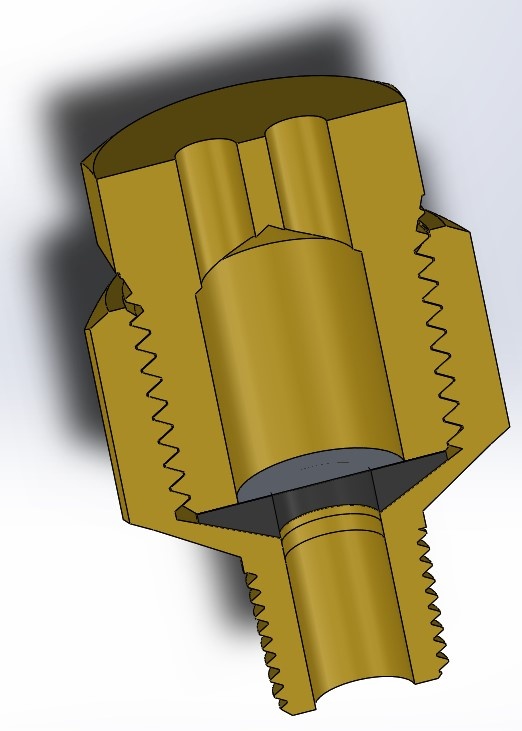

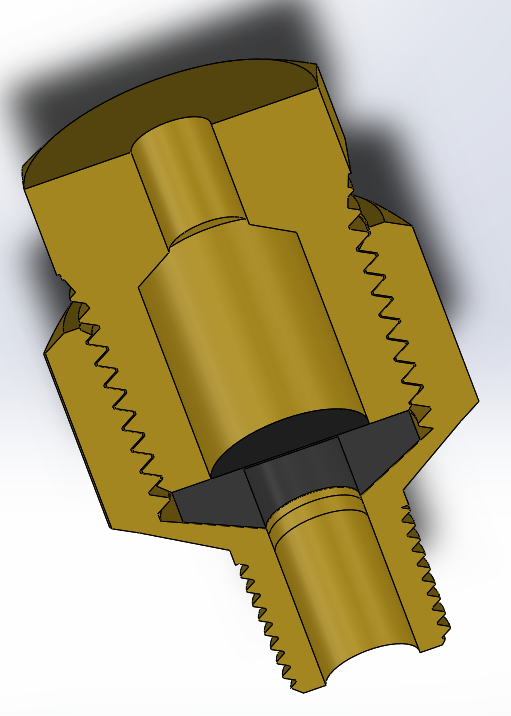

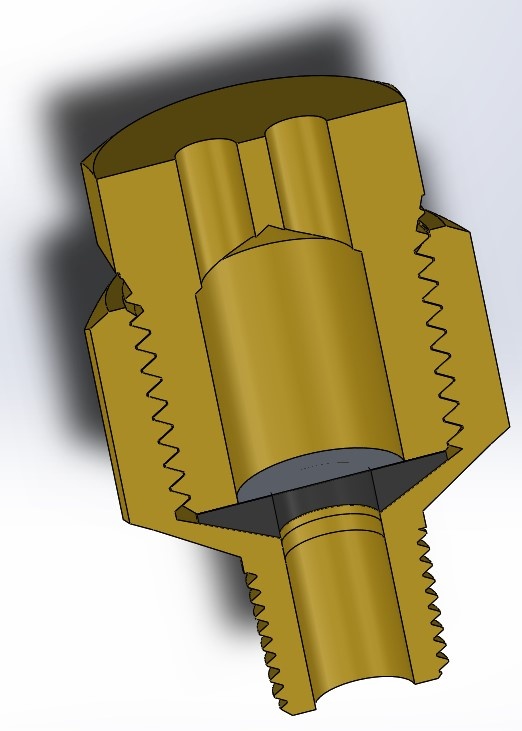

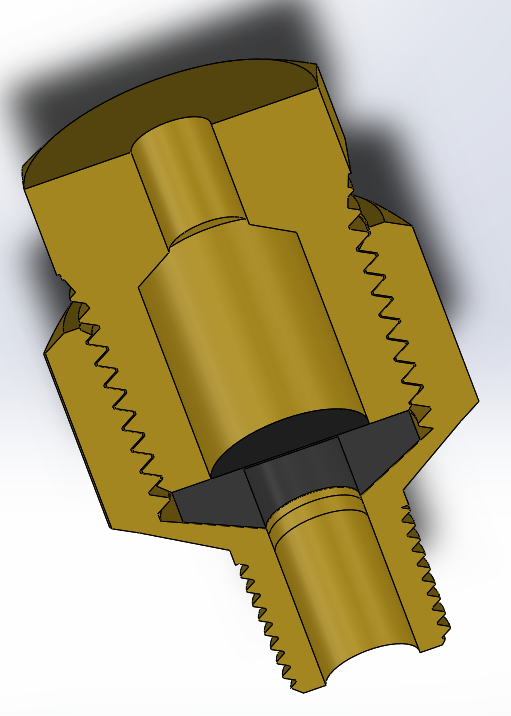

- Design 1:

- Reducing adapter 50785K612 (3/8" F x 1/8" M)

- Plug w/ ext. hex drive 50785K23 (3/8" M, hollow)

- Drill two holes for two e-matches

- Burst disc

- (Heavy duty?) aluminum foil with maybe an o-ring or something to hold pressure (might just work without it though, could use RTV gasket if necessary?)

- Tape (aluminum duct tape, maybe just regular tape would work)

- Angled washer to promote good sealing

- 3D print with a softer material (flexible resin? TPU?)

- Faucet washer: 2801K24 (kinda thick and not exactly the right angle/diameters)

Prototype Design 1:

- Design 2:

- Drill one slightly bigger hole instead of two holes to reduce machining time

- Replace the aluminum burst disk and instead add 1-2 printed layers to the angled washer to act as the burst disc

- Sealing on the washer probably not necessary, it just needs to contain the black powder granules, not be an airtight seal

- Can probably just print in PLA on an FDM printer (cheap and easy!)

{"serverDuration": 111, "requestCorrelationId": "6f33e845c1ef06de"}