- Materials: need DP-420 NS Epoxy for fillets and System 4000/4600 Hardener

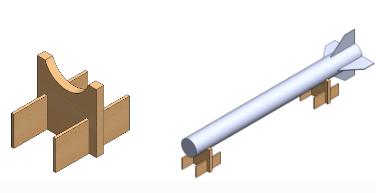

- Fin Manufacturing

- Waterjet G-10 Cores

- 5 Carbon fiber layups and sanding

- Leading edge

- emphasis on symmetry

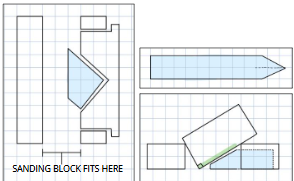

- Sanding board at angle is constrained by the 2 x 4s, fin is slowly slid in with different holders for each leading edge.

- need to calculate geometry for a defined inner angle

- NOTE: Created test fins, found that average thickness of carbon fiber layer was 0.009 inches.

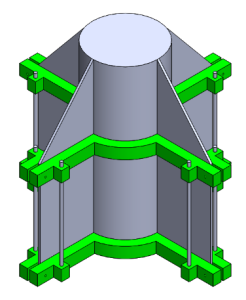

- Alignment Jigs

- Jig for fiberglass layups

- TLDR: old prometheus camera shell works better at Mach 1

- enacting ANSYS simulations need work because the results we have gotten are off in terms of magnitude

- Manufacturing

- 3D printed mold and fiberglass layups

- Testing Plans

- Need to test shell and camera under heat and load from drag

- TLDR: old prometheus camera shell works better at Mach 1