When designing fins for our rocket, we chose to make foam fins with a two ply carbon fiber layup over the top. The fins will be light, because they have a foam interior, and strong due to the carbon fiber layup.

To make the sandwich panel fin layups, follow these steps:

- Cut foam to the right shape and thickness (foam cutters and laser cutters work well)

- Sand the fin edges to create an airfoil shape (about a 45 degree angle)

- Cut two pieces of carbon fiber fabric per fin that are exactly the same shape of the fin

- Cut two pieces of carbon fiber fabric per fin that have a 1.5" overhang for all the fin edges. The fin tab (the part of the fin that connects to the fin can) should not have an overhang.

- Start by laying up the cloth with tabs and folding over the edges of the fins first

- Place an exact shape piece on the opposite side of the fin, and lay up this piece

- Flip the fin back to the first side and lay up an exact shape piece of carbon fiber

- Flip the fin to the second side and lay up a piece of carbon fiber with tabs

- Use mylar or hold the layup in your hands to keep it from sticking to the layup surface

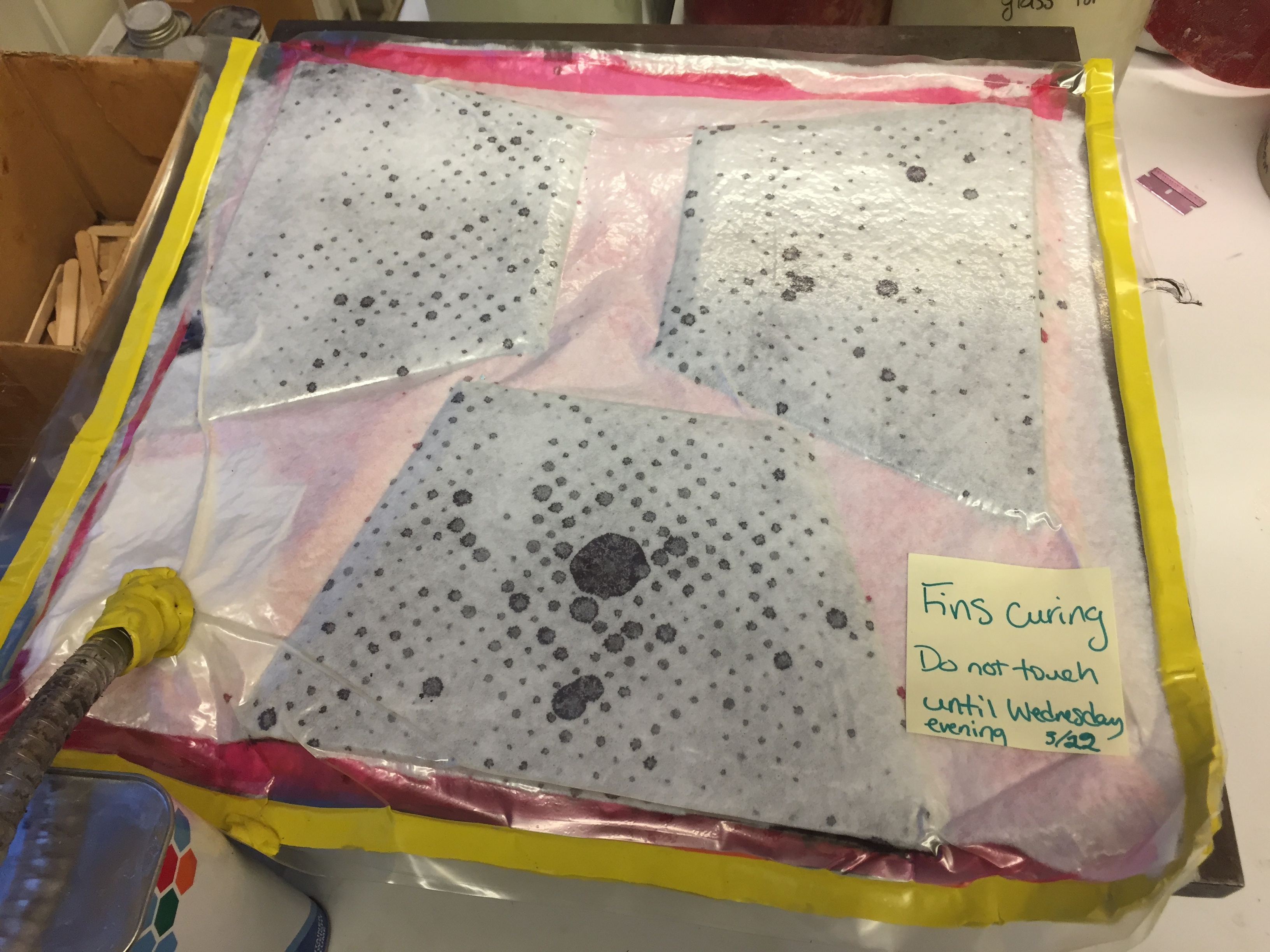

- Follow sandwich panel procedures to vacuum bag the fins.