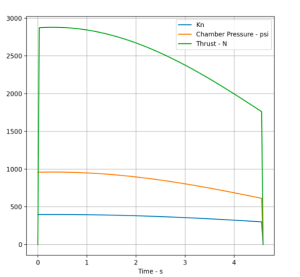

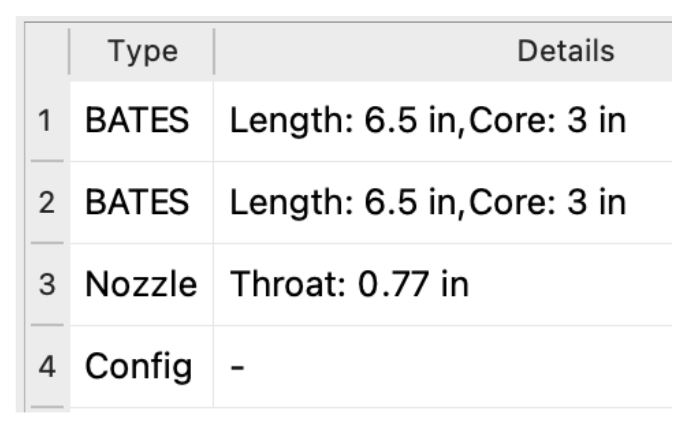

Overview

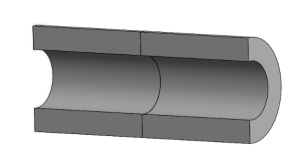

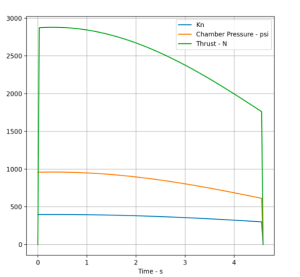

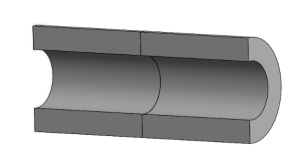

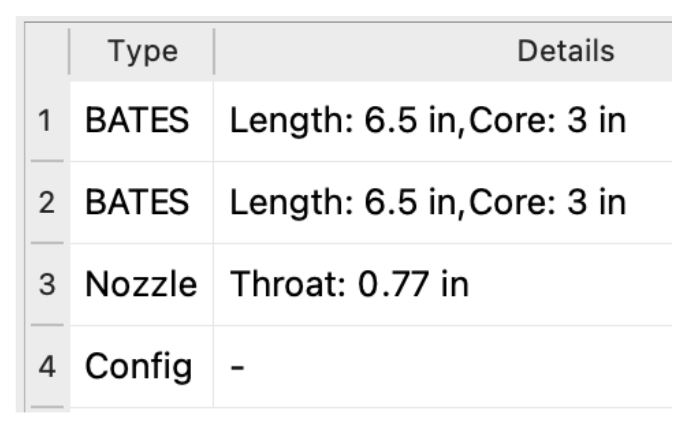

Grain Geometry

Went with cylindrical geometry, less complex than booster motor

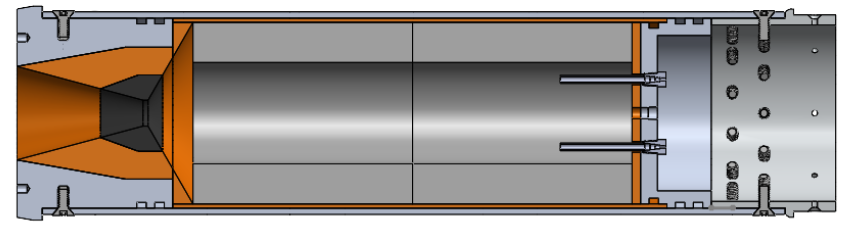

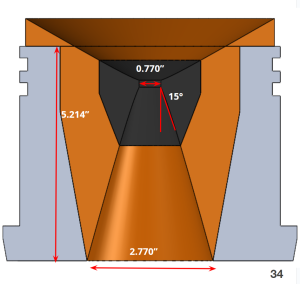

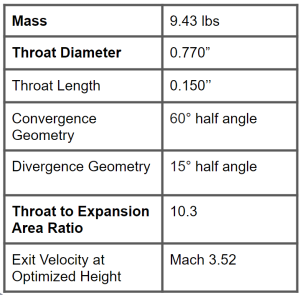

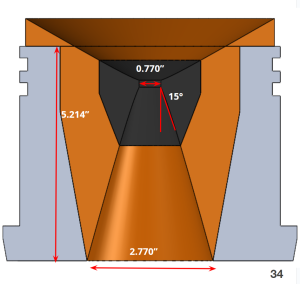

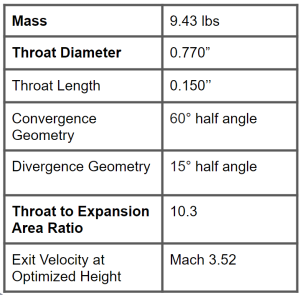

Nozzle

Withstand 2*max operating pressure of the chamber

Attach securely to booster case

Support the fin can under high acceleration

Optimized for 14350 ft above ground level (sum of 2/3 of height difference from ignition to burnout and ignition

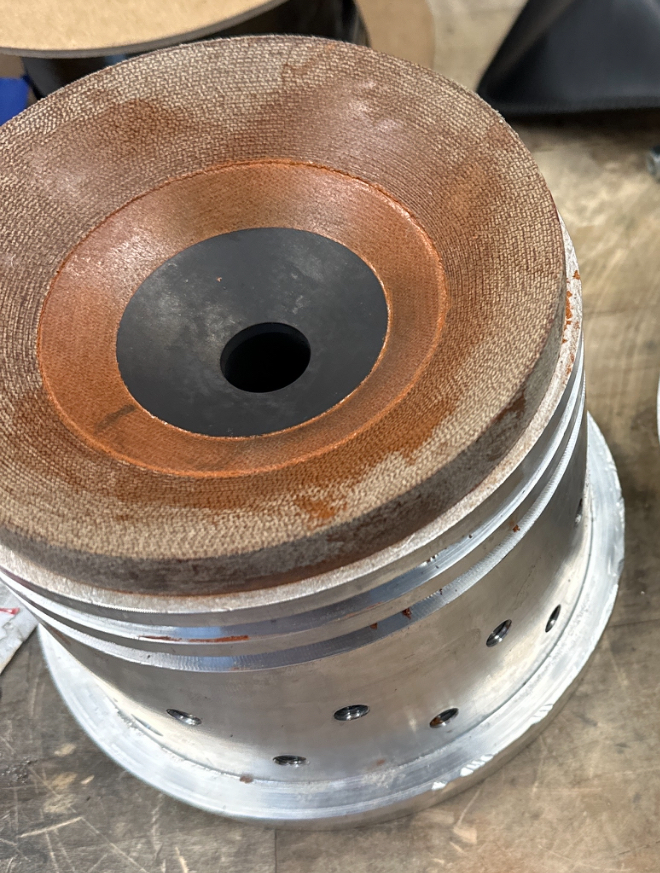

Materials

Aluminum 6061-T6

Canvas phenolic

Graphite

Decided to go with a concave convex nozzle rather than a bell nozzle like on the booster

Two part phenolic seemed smart in design, but in practice was difficult to manufacture

When making the top phenolic ring I got chastised by Todd for a completely infeasible design (was somehow able to manufacture it but it was super sketch, just had to face 500thou )

In the future it would be much better to make the phenolic into one whole part rather than two pieces

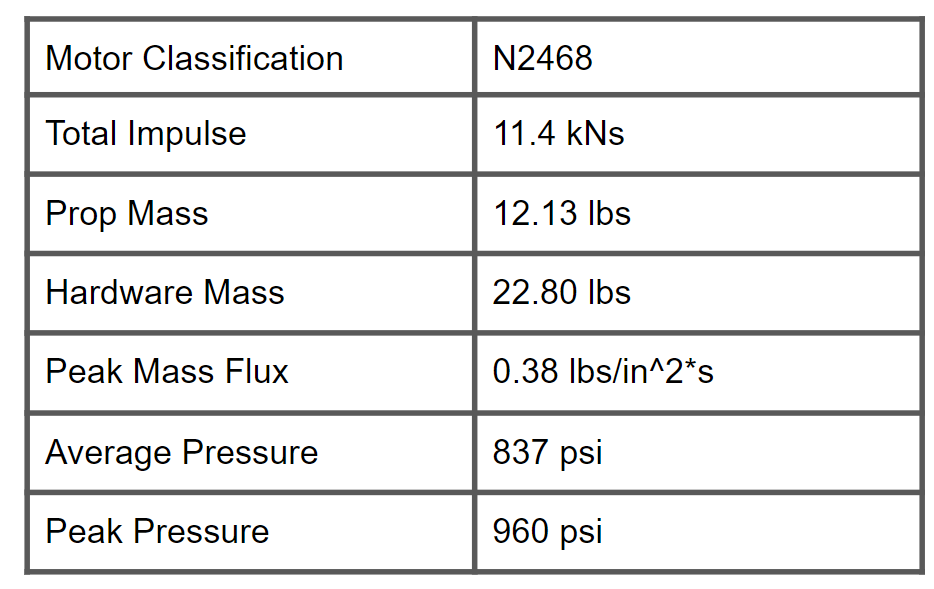

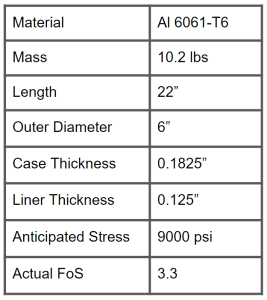

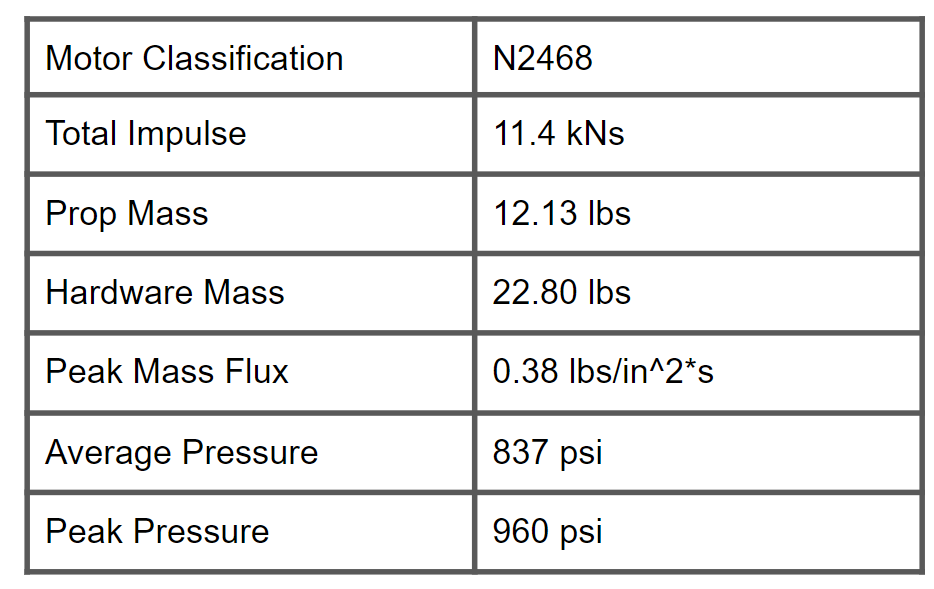

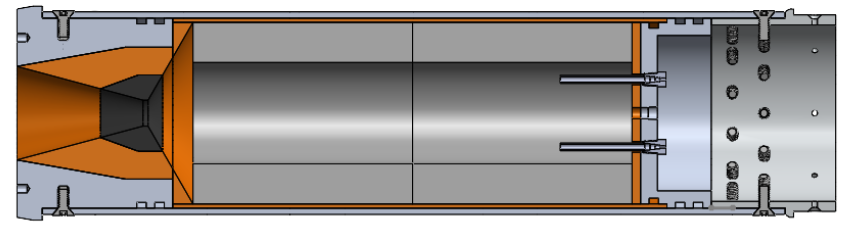

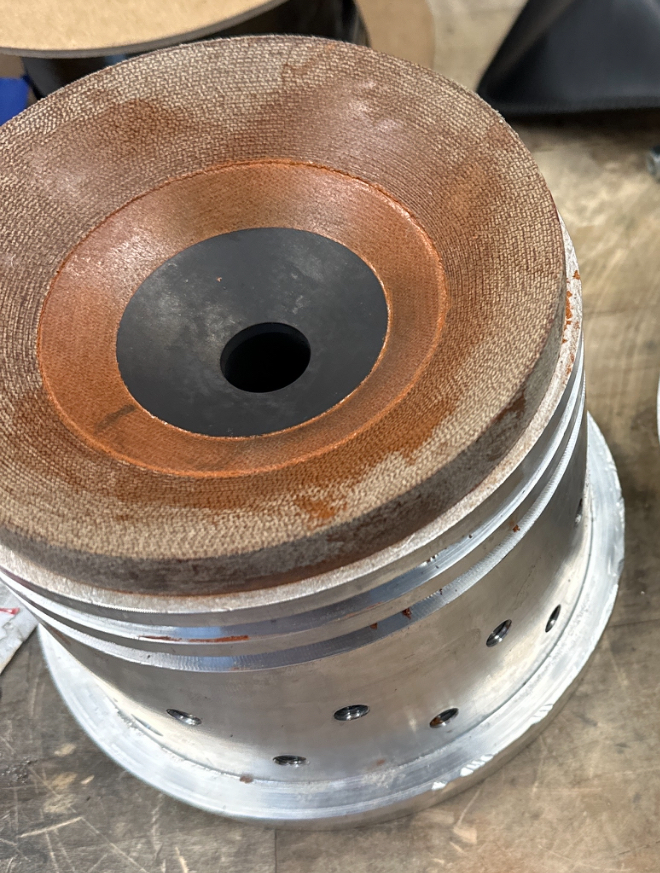

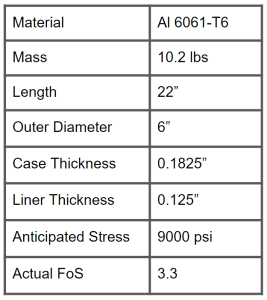

Case

Requirements

Withstand 960 PSI during burn

Withstand 1440 PSI for twice the burn time during hydrostatic test*

Utilize a FoS of 2*

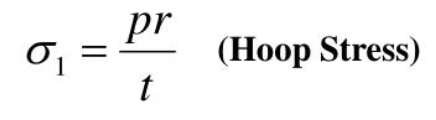

Hoop Stress Approximation

P = pressure

R = radius

t = case thickness

FRR, FC and Bolt Calcs

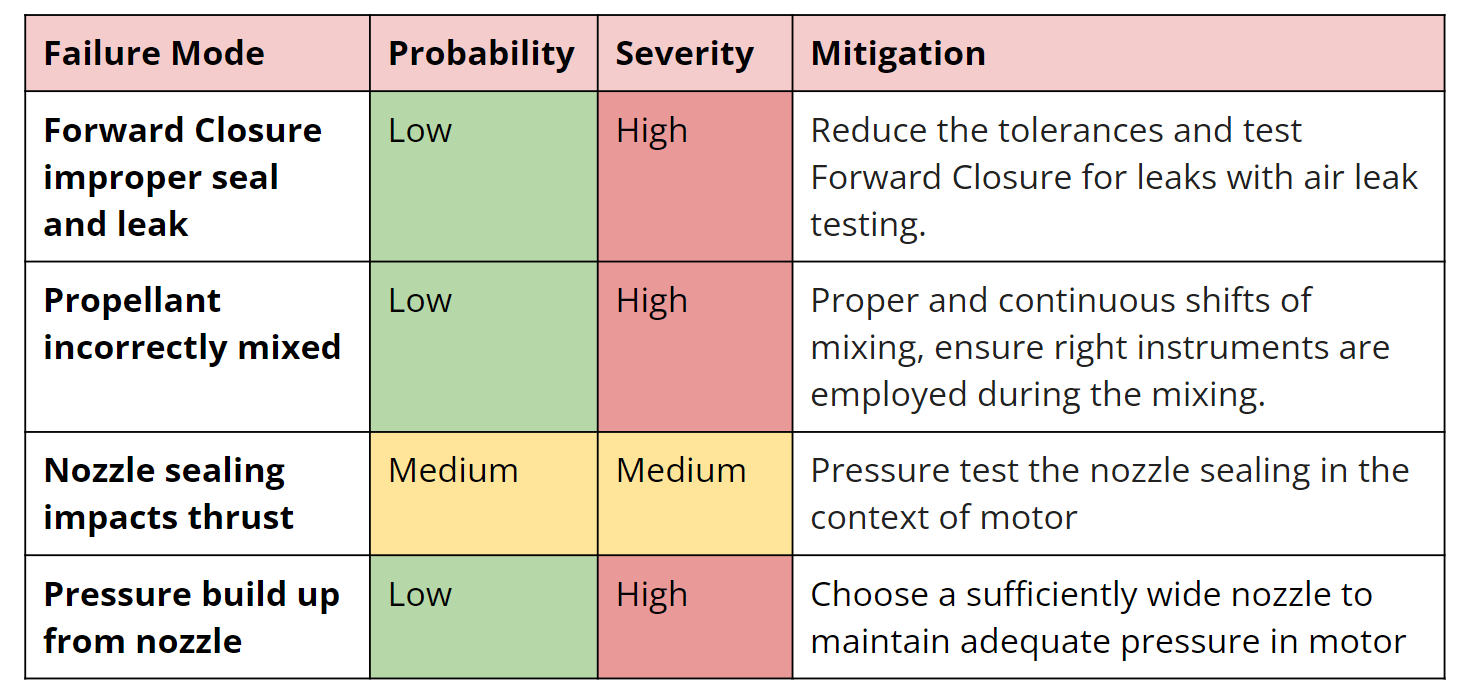

Safety Margins

{"serverDuration": 137, "requestCorrelationId": "ab6e9a62ae4ec38e"}