...

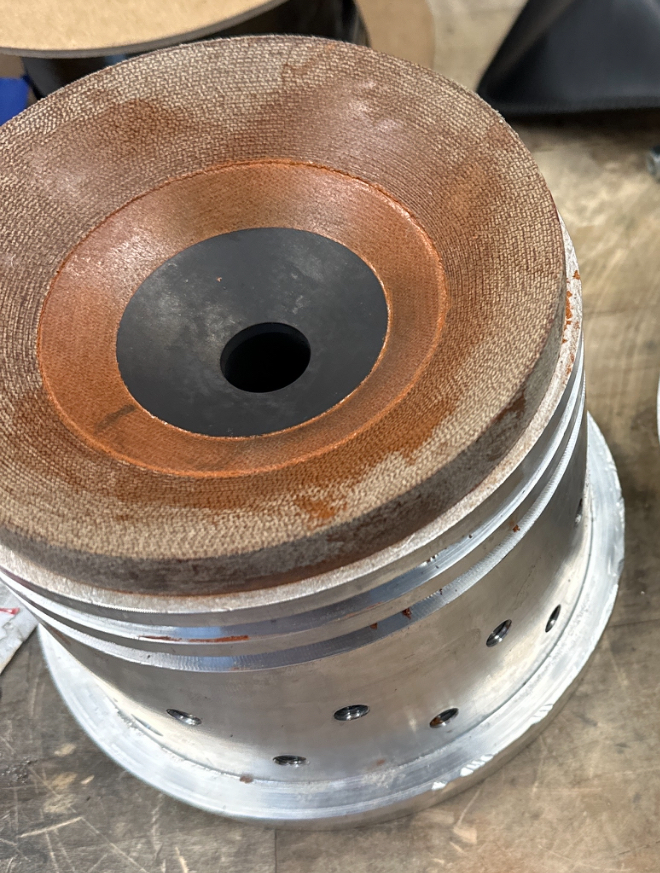

Decided to go with a concave convex nozzle rather than a bell nozzle like on the booster

Two part phenolic seemed smart in design, but in practice was difficult to manufacture

When making the top phenolic ring I got chastised by Todd for a completely infeasible design (was somehow able to manufacture it but it was

super sketch, just had to face 500thou)In the future it would be much better to make the phenolic into one whole part rather than two pieces

"Should not do 'pointy sides' of phenolic on the bottom" - Derek

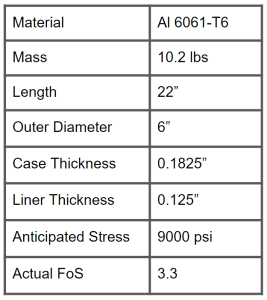

Case

Requirements

Withstand 960 PSI during burn

Withstand 1440 PSI for twice the burn time during hydrostatic test*

Utilize a FoS of 2*

Hoop Stress Approximation

Used linearized formula

P = pressure

R = radius

t = case thickness

...