Summary

From Spring 2023 to Spring 2024, onboard camera housings were designed and fabricated for projects Medusa and Prometheus. As a full redesign of its predecessor, the Prometheus aeroshell

Background

The need for new housings was made apparent after the launch of Project Phoenix in the IAP prior.

These were the Phoenix aeroshells (images from 2022):

And images from Phoenix Launch, after recovery (2023):

Two designs were made in parallel, one to hold the Runcam Split flight cameras and another to hold 808 Keychain Cameras. These aeroshells were 3D printed from SLA resin and bolted onto the mission package tube. After launch, multiple issues were identified in this design:

- Many of the cameras turned off on the pad, so they did not record footage. Overheating was identified to be the most likely cause.

- The cameras were turned on and the rocket left on the pad for an unexpected length of time (~1 hour).

- Since launch happened in January, the temperature outside was still chilly. The camera generates heat while operating, so the overheating most likely happened because its own heat was trapped inside the shell.

- They may have also absorbed heat from the warm sunlight.

- After recovery, some of the aeroshells were noticed to have a gummy or sticky surface texture.

- After launch, avionics placed another set of aeroshells outside in the sun, with cameras inside them. The experiment recreated the camera shutoff and sticky texture from launch.

- The stickiness could be due to improper curing of the resin print.

- Could also have been softening from in-flight heating (air friction, stagnation).

- The aeroshells required access to the inside of the tube to mount, as well as space for nuts on the interior. This can obstruct the AV bay from being inserted into the rocket, and requires the aeroshells to be integrated before anything else gets put inside.

- The shape is bulky, with many corners, flat faces, pockets, and protrusions that disrupt airflow. Phoenix had a significant (~10,000 ft) discrepancy between predicted apogee and actual apogee. The shape of these aeroshells likely exacerbated coning and increased drag on the rocket in a way that was not predicted in simulations.

- The aeroshell cracked on impact with the ground. This is fine, we don't need to design things to survive hitting the ground.

With the new design, we hope to fix the issues of the previous while improving the aerodynamic performance and thermal robustness.

Preliminary Designs and Research

In Spring 2023, Summer Hoss '23 led aeroshell redesign sessions. The goals were to conduct research and establish a preliminary design.

- Research was conducted to narrow down a set of materials that provided sufficient thermal insulation while being reasonable to buy and fabricate with. These materials ended up being:

- Nylon 66 3D print - somewhat more heat-resistant than PLA or SLA, though still runs the risk of softening.

- carbon fiber - very heat-resistant. Pure carbon fiber may soften from heat, depending on the thickness. May be difficult to work with, given the size of the aeroshells and the team's level of experience with composite materials.

- Other composite materials - same as carbon fiber, but the team has limited experience with it.

- Some design ideas were generated:

- Incorporating a mirror so that the camera can be oriented differently from the direction we want a recording of.

- In-flight vibrations were found to not interfere with this type of design.

- Incorporating air pockets for increased insulation

- Using aerogel

- It's expensive

- Using honeycomb structures such as Nomex

- Adds a lot of thickness

- Using aerogel

- Relocating the onboard cameras to inside the rocket.

- People really wanted them on the exterior though.

- Using the shape of the existing but unused aeroshell CAD model made by Chad Meier '23.

- Incorporating a mirror so that the camera can be oriented differently from the direction we want a recording of.

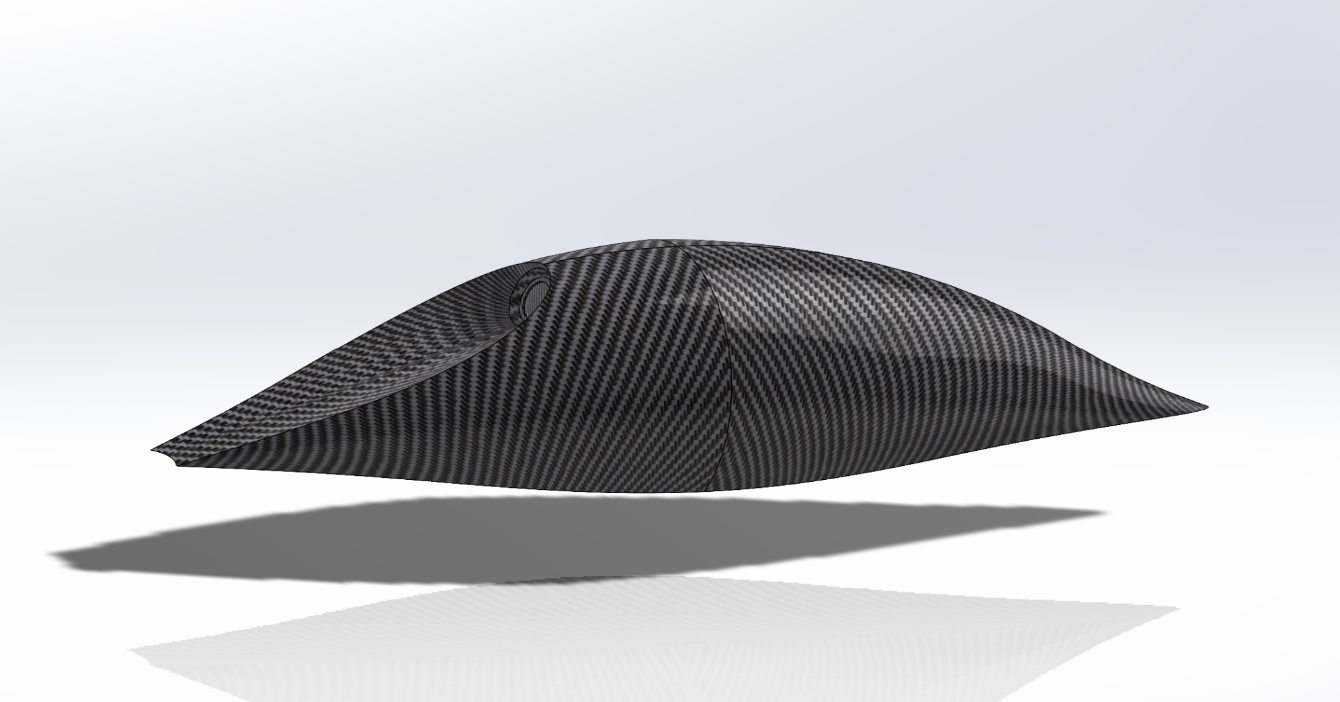

In Fall 2023, the design of the aeroshells became a collaborative effort between the Medusa Aerodynamics and Prometheus Structures subteams. Interested members cooperated to produce rough designs for the Medusa conceptual design review (CoDR) and preliminary design review (PDR), slides linked. These were designed for the 808 cameras, to be made with T300 standard modulus twill weave carbon fiber and withstand a maximum in-flight temperature of 1300°F. A negative mold would be made for them using foam and a CNC router. After preparing the mold, the carbon fiber would be laid up and vacuum bagged. Ideally, the part can be left to cure in a composites oven so that it attains a higher operating temperature. We obtained access to Prof. Zachary Cordero's composites oven in his lab for this purpose. Post processing would be done to create holes for mounting these to the mission package tube.

For the Medusa conceptual design review (CDR), the development of the aeroshells shifted to be more the responsibility of the aerodynamics subteam. Design changes were made so that the shells could be more easily fabricated and design details were further developed. Thermal simulations were attempted, but unsuccessful. The slides are attached here.

This design involves two plies of carbon fiber over a 3D printed frame, with heat-resistant paint applied to the exterior as an ablative coating.

Design Development

After the cancellation of Project Medusa, the remaining members of the Medusa Aerodynamics subteam (Vealy Lai '26, Conrad Casebolt '26, Ethan Wong '26) were absorbed into Project Prometheus and turned their primary focus to developing the aeroshells. With renewed efforts, a clearer design process was defined for this component.

Goals [TBD, KEEP WRITING HERE - VL 5/5/24

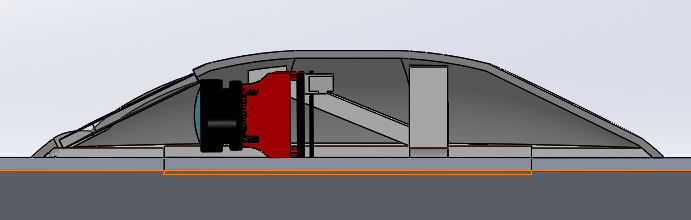

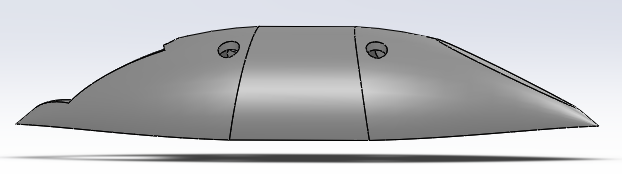

The aeroshells, of which there are four (4), shall be mounted to the outside of the mission package tube on each stage. Each aeroshell must contain and protect a camera which records the flight of the rocket. The upward facing aeroshells shall capture the deployments of the recovery systems. The downward facing aeroshells shall capture the ignitions and staging.

The aeroshell design must be streamlined in shape to minimize drag.

The upward-facing and downward-facing aeroshells must be aerodynamically similar to the greatest extent possible.

The aeroshell shall thermally insulate the camera from both the external thermal loads of in-flight drag and the stagnation temperature experienced by the rocket.

The camera must not overheat inside the aeroshell when left on (includes pad time and flight time).

Aerodynamic Design

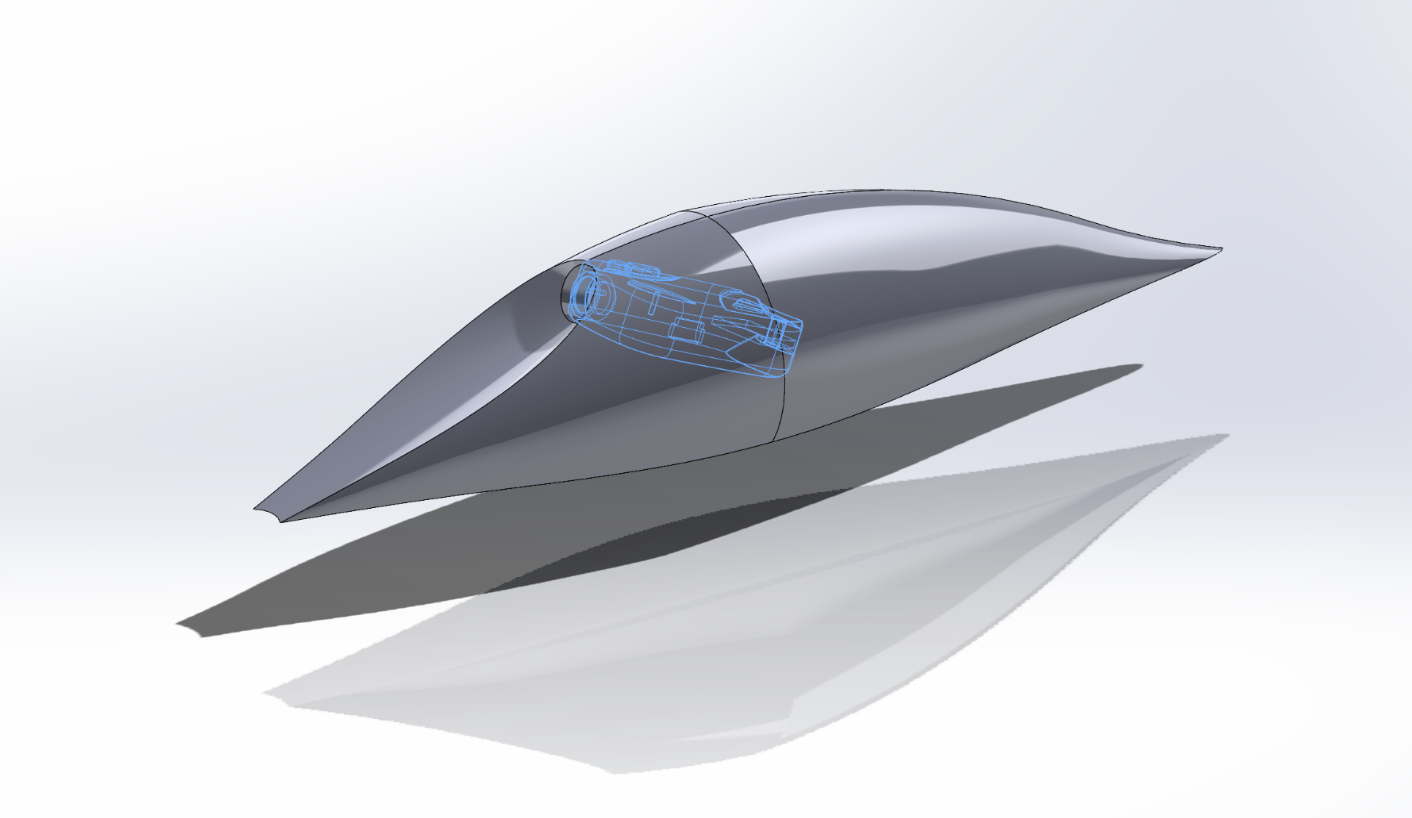

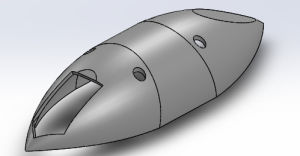

The aeroshell is streamlined on both ends. Its diameter is only minimally larger than the Foxeer Camera which it houses.

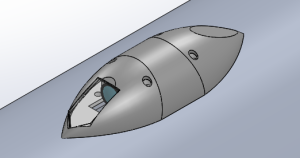

(Previous Iteration of Aeroshell IAP 2024)

Aerodynamic Testing

CFD analysis will be performed in the future.

- Update 5/5/24: No aerodynamic or thermal simulations have been conducted on the aeroshells

Manufacturing (Nov. 2023)

The aeroshell mold is 3D printed using PLA. A piece of heat resistant glass is cut to the required shape. Three layers of carbon fiber are attached to the exterior of the mold with an epoxy layup using a vacuum bagging technique.

- We performed this procedure for two first-iteration aeroshells, but the carbon fiber did not bind well to the outside of the aeroshell. It is difficult to map the planar sheet of carbon fiber onto the steeply curved exterior of the aeroshell. As a result, a negative mold may be used in the next iteration.

Thermal Testing

In order to recreate the thermal loads experienced by the aeroshell, the aeroshell will be exposed to the stagnation temperature of 350°F using a heat gun for one minute. It will be mounted to a piece of fiberglass to emulate the exterior of the mission package tube.

- Thermal testing concluded that fiber glass is a better choice of composite for the Aeroshell compared to carbon fiber. An identical fiber glass aeroshell maintained a lower internal temperature compared to a carbon fiber counterpart.

Current Design (April 2024)

Overview

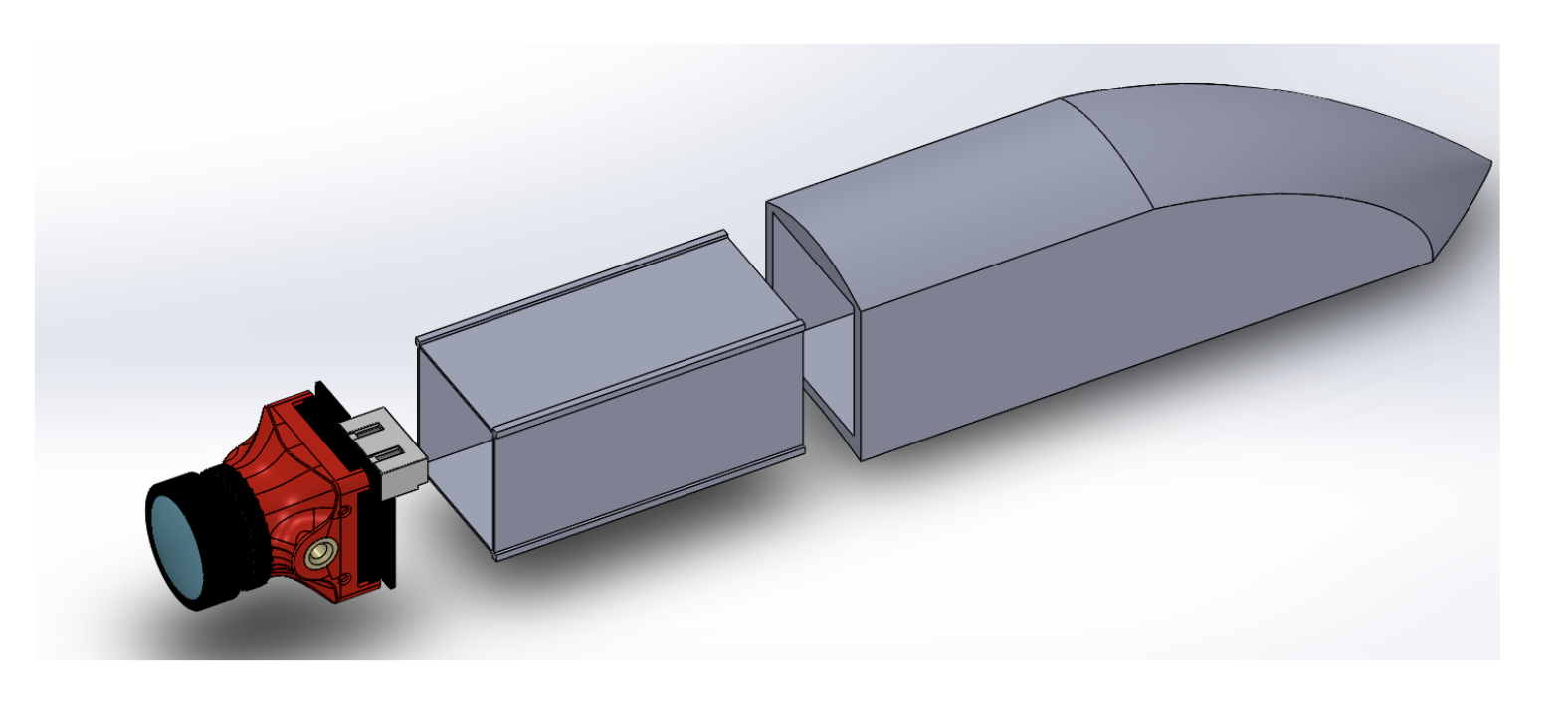

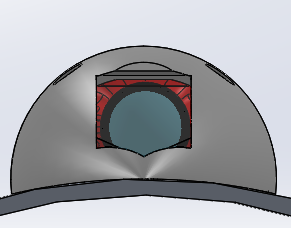

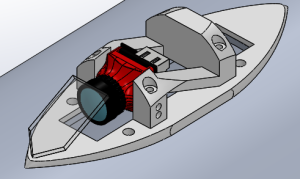

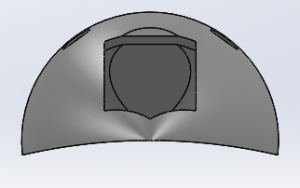

The current design features two separate parts: The Shell and the Skeleton. There is also a glass panel attached to the end of the viewing aperture and camera.

Shell

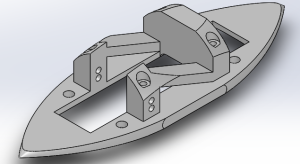

Skeleton

Manufacturing

Due to the non-planar shape of the shell, the only viable method of manufacturing is to use a negative mold with composite-epoxy layups sealed in a vacuum bag. The general overview of the process is as follows:

- Print a negative mold of the shell using PLA.

- Perform three consecutive epoxy layups in the negative mold using three layers of fiber glass composite, abiding by the general procedures of epoxy layups.

- Vacuum bag the negative mold and hold near/complete vacuum for 24 hours using a vacuum pump.

More detailed instructions can be found here.

Results

These Aeroshells flew on the Prometheus test flight in April 2024. All four remained intact through subsonic flight speeds and an estimated apogee of 5,000 feet (**double check this CC 5/16/2024). Only one Aeroshell carried a live camera, and the footage captured was deemed sufficient documentation of the booster recovery system deployment. The camera did not overheat during flight or on the pad.

Integration

The two-piece approach necessitates the following integration steps:

- Mount the skeleton to the mission package tube using four (4) M3 or 1/8" screws and corresponding nuts, with the nuts inside **or outside? CC 5/16/2024** the MPT.

- Attach the camera to the skeleton and connect the camera to the avionics bay.

- Mount the shell to the skeleton using four (4) M2 screws.

Future Design Improvement Ideas (as of May 2024)

- The exterior screws should be angled to keep the screw heads normal to the face of the exterior shell.

- The exterior screws are currently threaded directly into the PLA of the skeleton. A future design should add a threaded metal component on the skeleton in order to better secure the assembly together.

- The aerodynamics of the up- and down-facing aeroshells are similar but not identical. Perhaps a new glass shape could be designed, or non-planar glass could be used.

- The cross-sectional profile could be further reduced by using a parabolic shape instead of circular, although a redesigned shell must retain adequate room for the structural supports of the skeleton.

- The field of view could be increased.