Overview

This is a first pass mechanical sizing of fin can structural requirements. It makes a lot of conservative assumptions.

- The fin core, fin roots, and fin fillets have no stiffness and bare no load

- The carbon fiber plies are .010 in thick

- The composite matrix has no compressive strength

Load Estimation

The fin's weakest axis is reacting moments around the root of the fin. To size the carbon fiber tip to tip layup for this case we need to estimate the moment around the root of the fin. From aerodynamics the force on the fin is

| (1) | F_{fin} = \frac{1}{2} C_L \rho V^2 |

Integrating this over the length of the fin we can obtain the moment

| (2) | M_{fin} = \frac{1}{2} C_L \rho V^2 \int_{0}^{H}c r dr |

c = chord length at fin height r

H = height of fin

Structural Calculations

From constitutive relations we can write the following

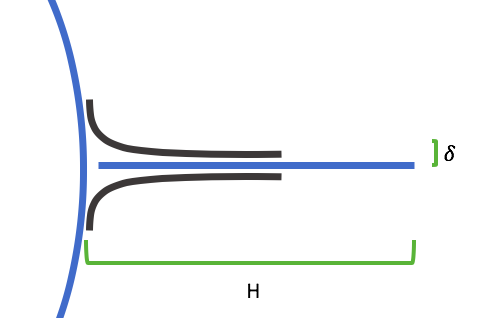

| (3) | M = F*\delta = \sigma*\delta*A |

| (4) | \sigma = \frac{M}{\delta*A} |

Now knowing \sigma_{max} we can calculate the number of plies of carbon fiber we need at a give factor of safety to meet load cases.